LIFTING TIPPING LOADERS

Our range of lifting-tipping loaders is suitable for product handling in the meat, poultry and fish processing lines and in the food technology industry in general.

These machines are made entirely of AISI 304 stainless steel. They are designed to meet the hygiene and safety standards required by the food industry and fulfill CE requirements.

Lifting – Tipping loaders for trolley 200/300 lt

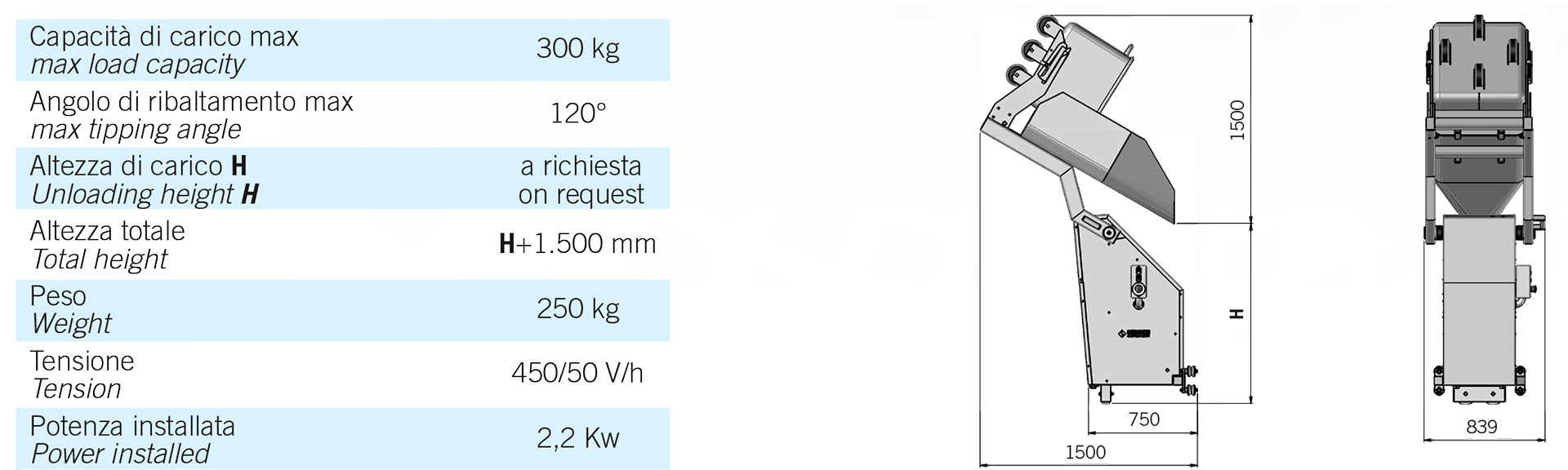

LOADER RCV

Lifting-tipping loader for 200/300 Lt trolleys, electric motorized chain drive. Compact, lightweight and easy to maneuver is usually rail-guided attached to our Tumbler, can also be mounted on wheels for use in a variety of settings.

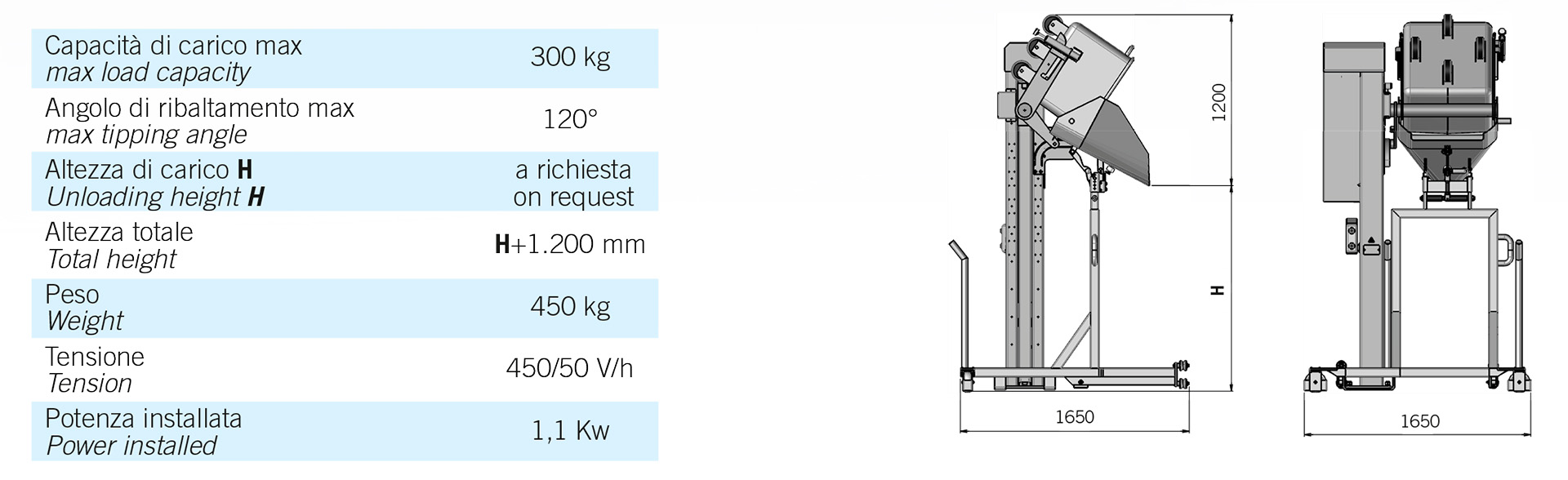

LOADER RCI

Column tilting lift for 200/300 liter trolleys, motorized chain drive. Light and versatile, it can be mounted on wheels or guided on rails to load in-line machines.

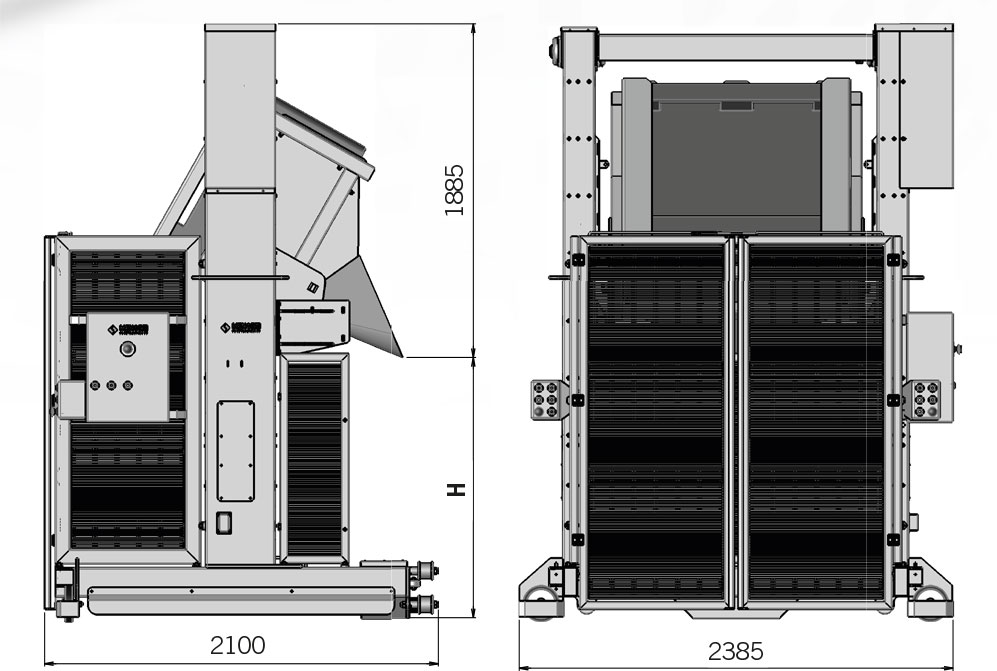

Lifting – Tipping for bins

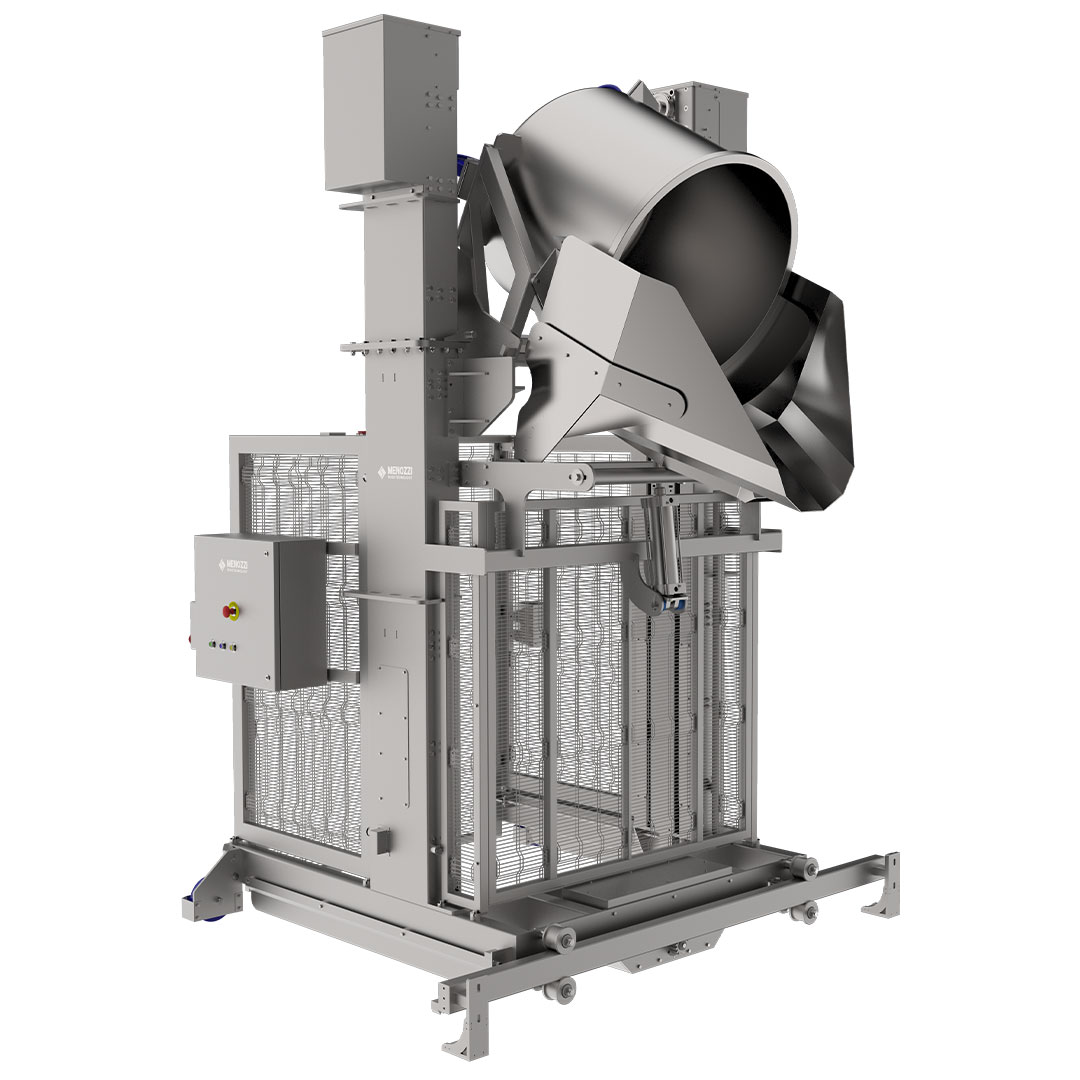

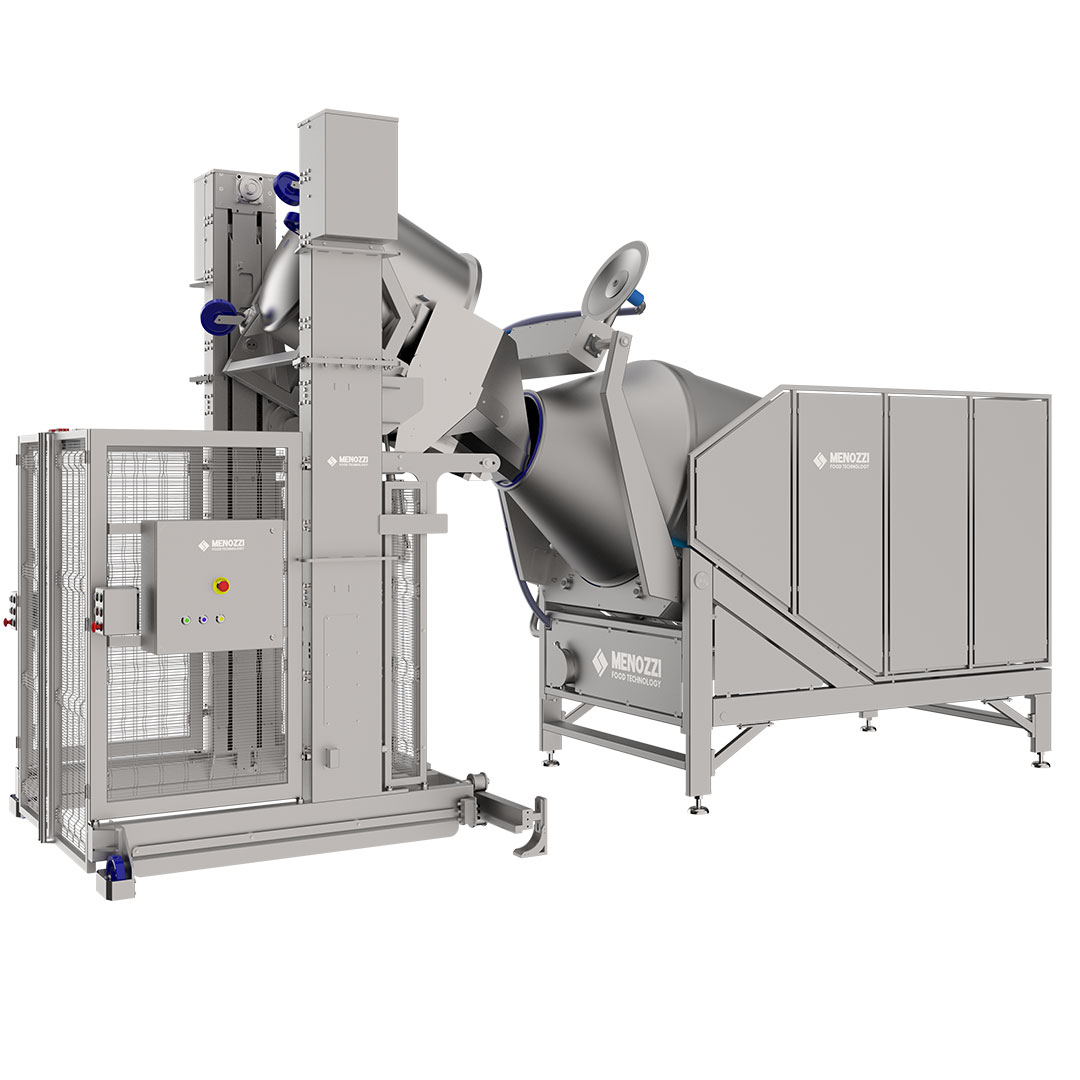

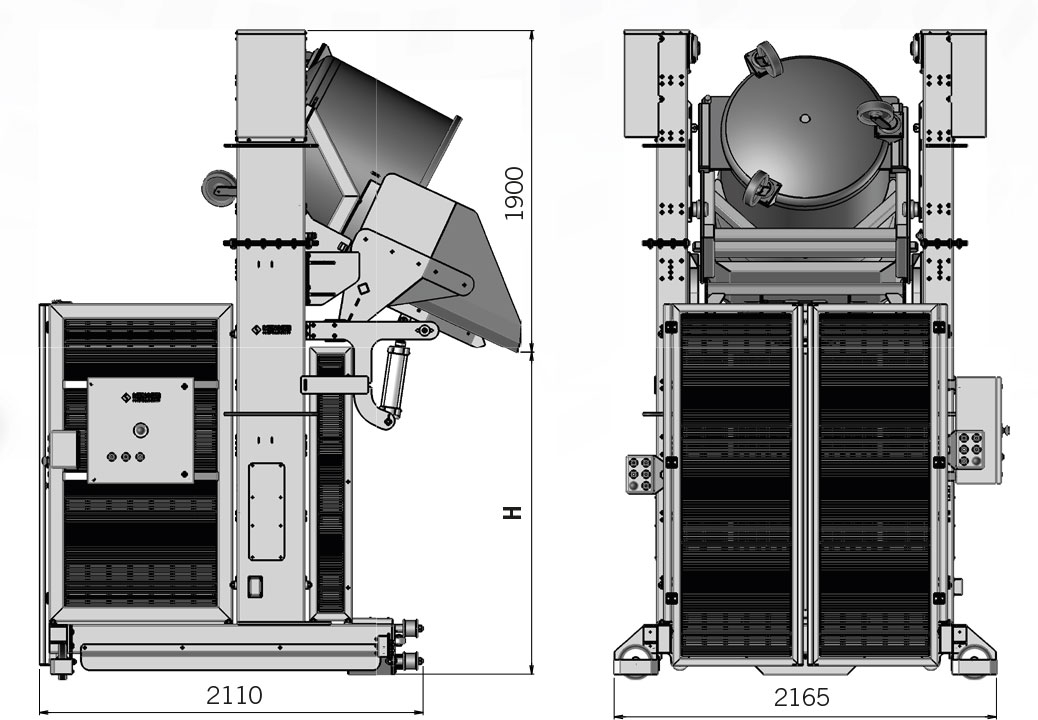

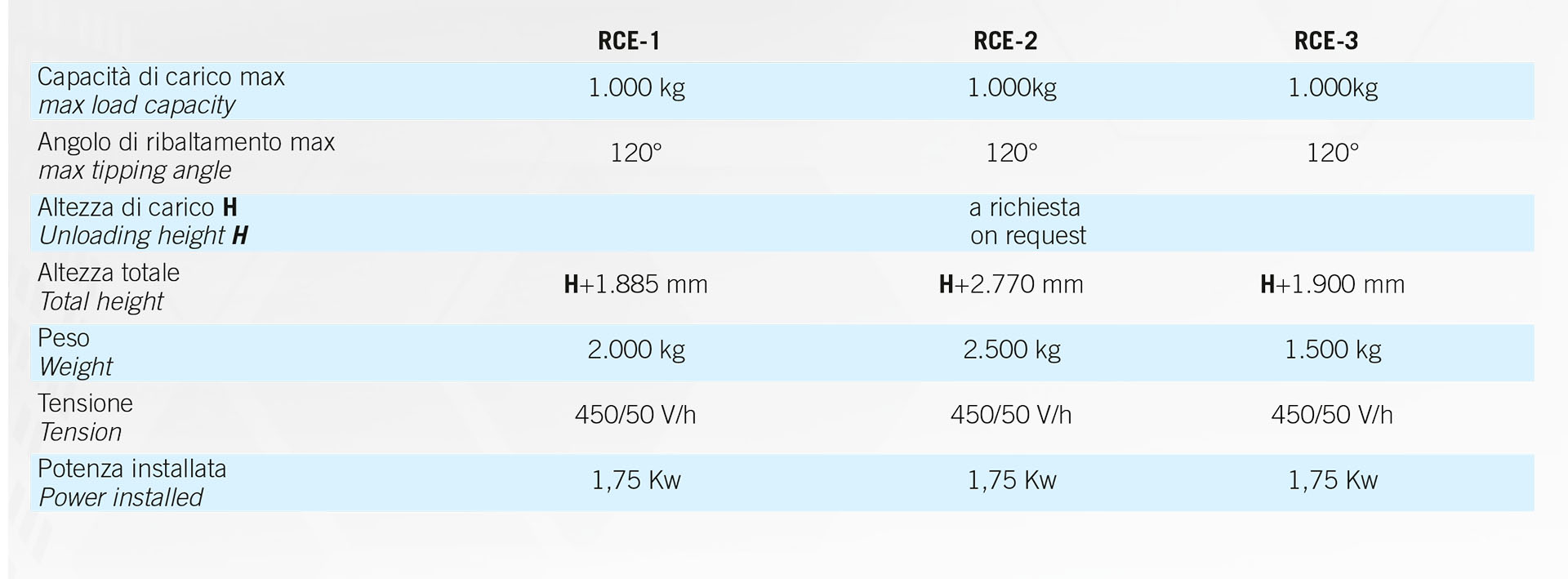

Tilting lifter for bins up to 1000 kg, both rectangular and cylindrical. The bin is lifted by two columns with a double motorized chain, single motor. The safety gate is completely openable at 180° and it’s provided with a locking system that activates as soon as the bin start to go up, making the loading area inaccessible. The lateral translation takes place by means of a motorized rail with a dead man switch. In case of chain breaking the loader is equipped with a mechanical fall arrester.

RCE -1

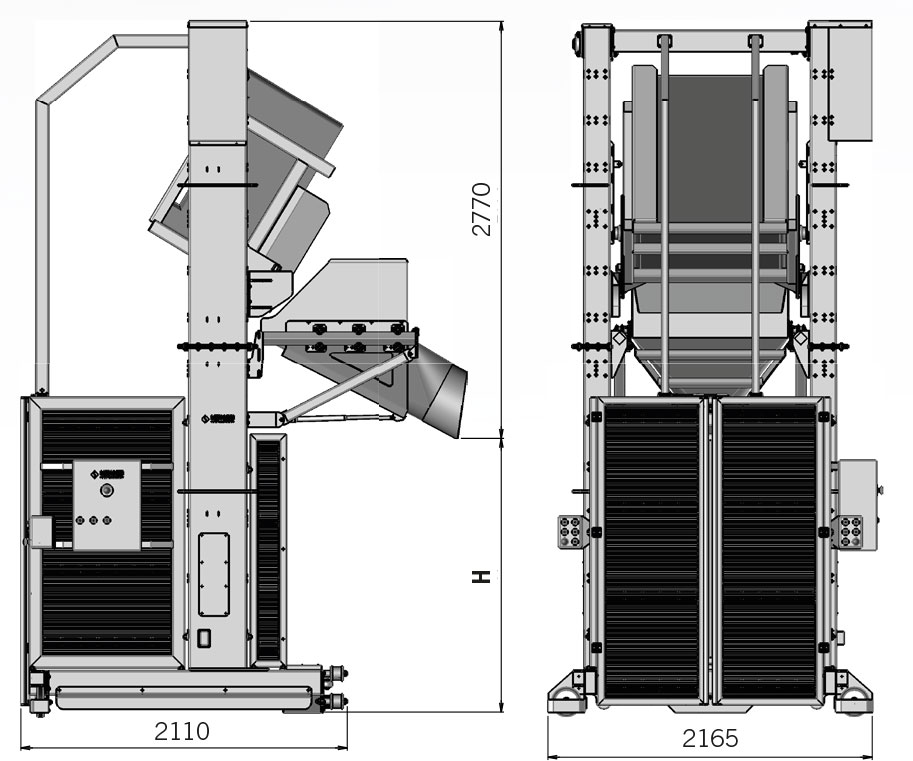

RCE -2

RCE -3

Tilting lifter for bins up to 1000 kg, both rectangular and cylindrical. The container is lifted by two double chain columns and two synchronized motors. The safety gate is completely openable at 180° and it’s provided with a locking system that activates as soon as the bin start to go up, making the loading area inaccessible. The lateral translation takes place by means of a motorized rail with a dead man switch. In case of chain breaking the loader is equipped with a mechanical fall arrester.

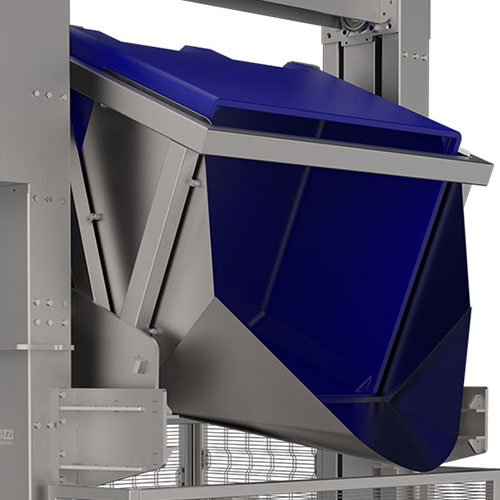

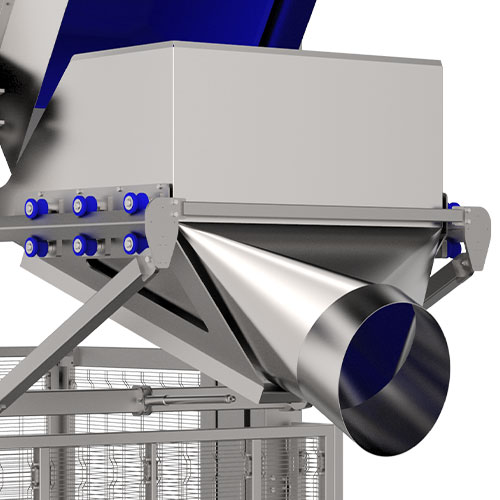

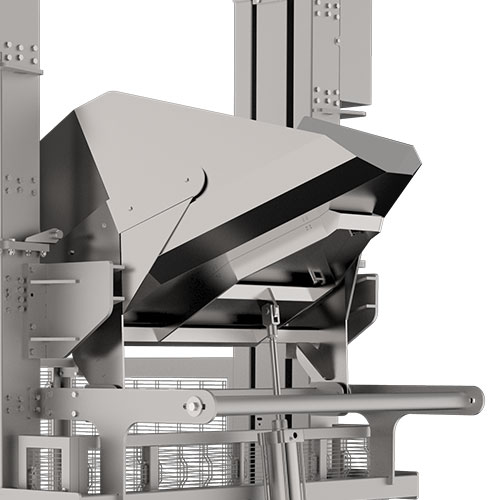

hoppers

built in hopper

sliding hopper

titling hopper

Complete massaging system with motorized translation loader, automatic positioning in front of the tumblers.

Both tumblers and loader are provided with an interconnected sensors system in order to prevent incorrect movements and collisions, so to guarantee a very high safety for the operator