twin -rail

conveying system

The overhead transport system was introduced for the first time in the meat industry

By Menozzi Luigi & C. S.P.A a leading company in the Food Technology market.

YEARS OF EXPERIENCE

PLANTS BUILT

METERS OF TWIN-RAILS INSTALLED

twin-rail

A twin-rail air transport system for all needs

Each project and each installation is developed according to the different needs of each product and of each customer. This system is in fact very versatile and can be utilized in the production line of each meat product, to be cooked, to be seasoned or smoked.

This allows large quantities of product to be transported and stored easily and smoothly while minimizing labor, making the best use of space, and ensuring the highest hygienic standards required by current regulations.

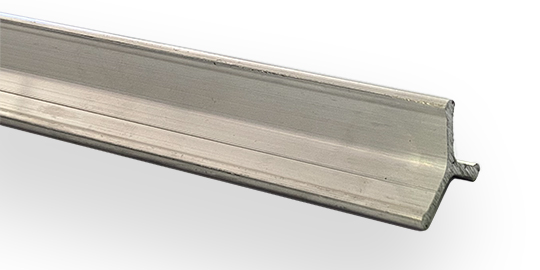

Stainless steel twin-rail

The Twin Rail system is available in two variants, AISI 304 stainless steel or aluminum, depending on the load to be supported.

- OPTIMIZATION OF SPACE AND LOGISTICS

- REDUCTIONS IN LABOR COSTS

- MAXIMUM HYGIENE

directional switches

The switches are direction devices positioned in the intersection points of one rail with the other. The operator sets the switches according to the direction the hanging racks must follow.

Each switches can be handled manually by a wand system or automated with a pneumatic or electric handling system.

When the twin rail needs to cross any door, such as room doors or fire doors or cooking chamber doors, the door crossing is enabled by a pneumatic connection device acted by door opening and closing.

2-ways

4-ways

3-ways

doorway

lowering/lifting units

A twin-rail air transport system for all needs

Each project and each installation is developed according to the different needs of each product and of each customer. This system is in fact very versatile and can be utilized in the production line of each meat product, to be cooked, to be seasoned or smoked.

This allows large quantities of product to be transported and stored easily and smoothly while minimizing labor, making the best use of space, and ensuring the highest hygienic standards required by current regulations.

Stainless steel twin-rail

The Twin Rail system is available in two variants, AISI 304 stainless steel or aluminum, depending on the load to be supported.

- OPTIMIZATION OF SPACE AND LOGISTICS

- REDUCTIONS IN LABOR COSTS

- MAXIMUM HYGIENE

automations

The Twin-Rail Conveying Sustem can be automated at multiple points along the route with the following devices:

- PALLETIZING

robots for racks to load/unload the product.

- MECHANIZED LINES

which allow automatic advancement of frames and scales, are particularly useful near accumulation lines, machinery such as washing machines and palletizers. They are also used inside the curing and smoking rooms to recirculate the product and evenly expose it to air conditioning.The mechanization of the lines can be either pneumatic or electrically motorized, and handling is done by stepper pushers or by means of a chain system that also allows bidirectional movement.

- LEVEL VARIATORS

That allow any unevenness in the structure to be overcome

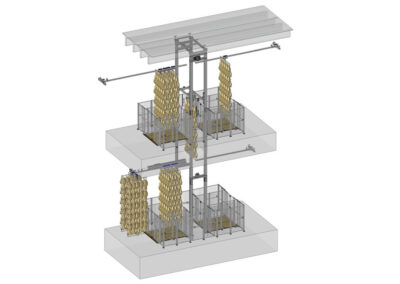

- ELEVATORS

That allow the transfer of one or more frames to different planes

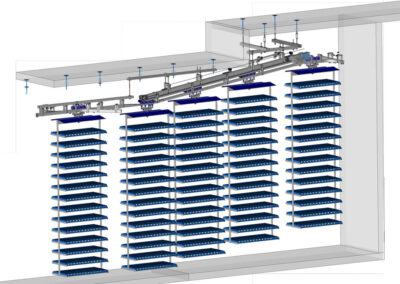

- TRANSFER SHUTTLES

capable of autonomously locating, grasping and transferring the chassis to predetermined points, ideal for long straight transfers, transfers between departments and accumulation lines.

shelves

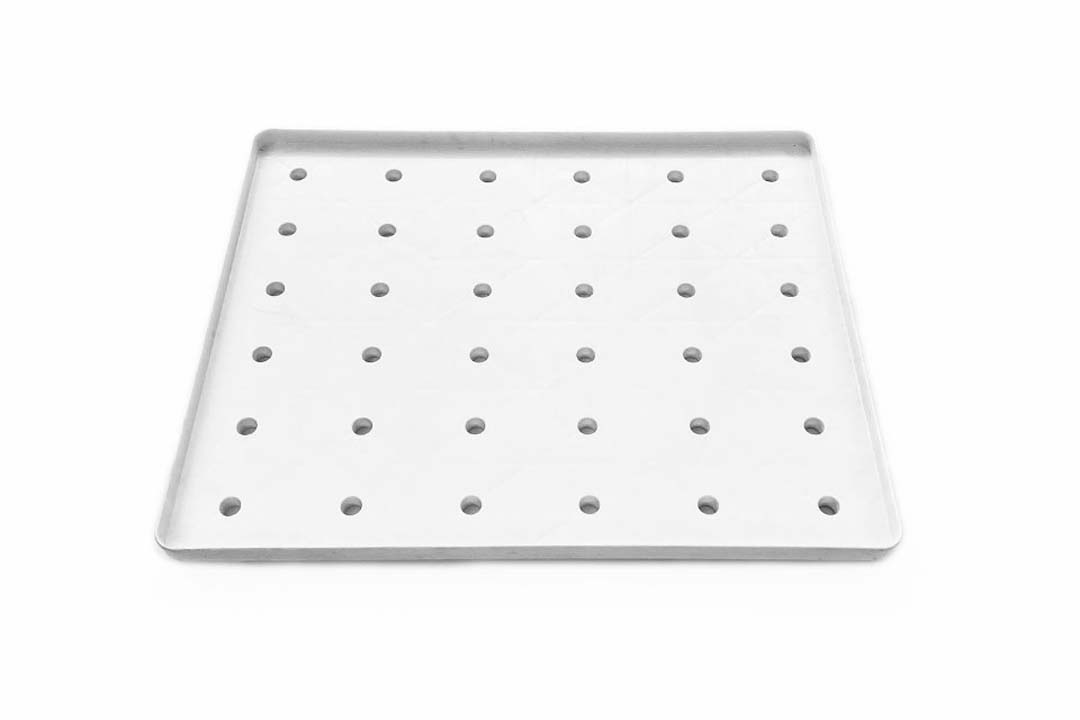

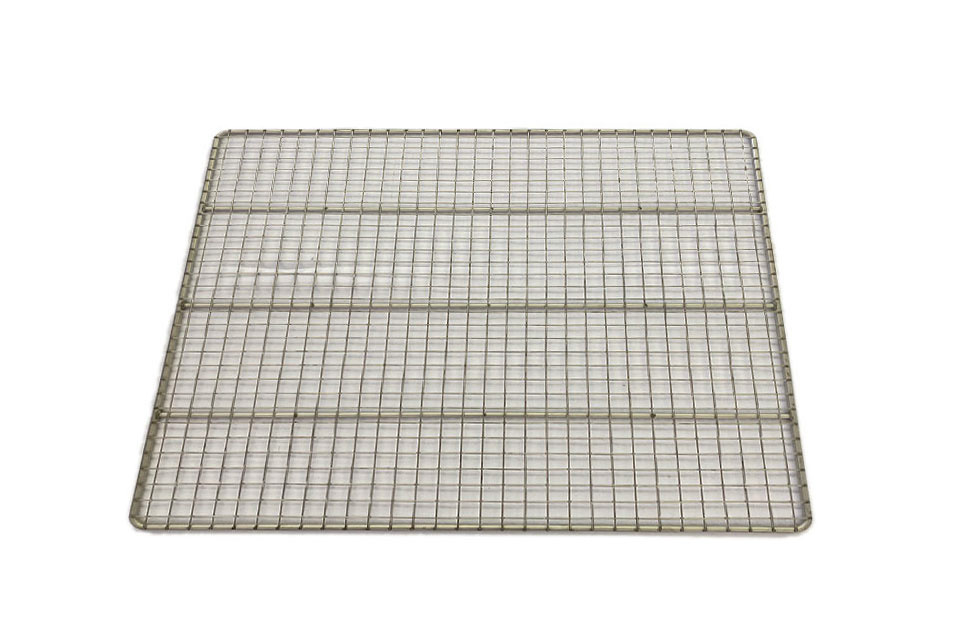

This kind of rack is used for lying products, such as hams or bellies in the salting phase, or speck/bacon and bresaola also in seasoning phase.

Each rack is customized according to the needs of each customer and of each product.

Also the shelves themselves are different in shape and material: plastic (smooth or ribbed) or stainless steel, (sheet or net)

plastic shelves

stainless steel net shelves

racks with nails

The Racks with nails are suitable for hams, traditional speck and bacon, that is for products to be hang by twine. Also in this case each rack is customized.

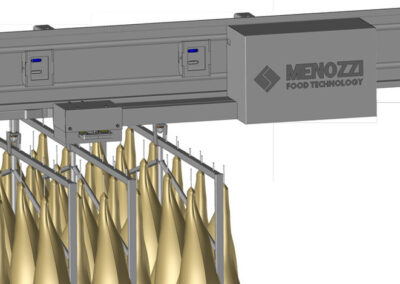

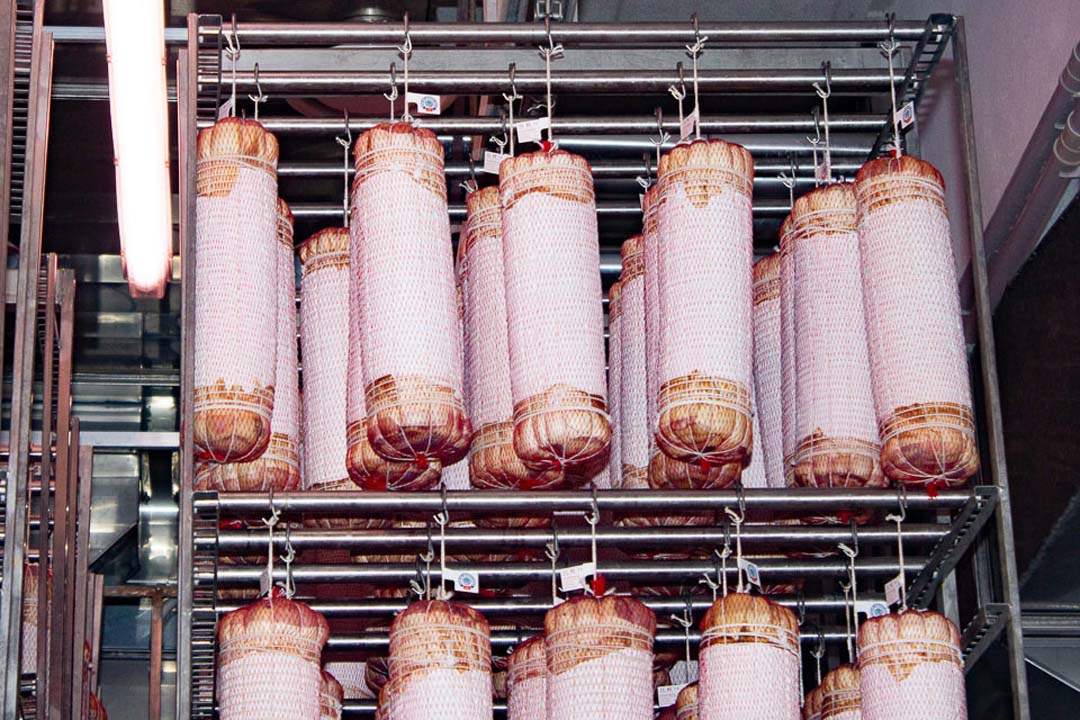

hanging racks for sticks

The racks for sticks are normally employed for each product that must hang in the seasoning, drying or smoking phase, such as salami, rolled bellies, rolled pork necks, kabanos and so on.

These are easy to adapt to any product size and can be automatically loaded and unloaded by any automated device.

A wide range of sticks, both of stainless steel or aluminium, are available to complete these racks.

stainless steel sticks

aluminium sticks

special sticks

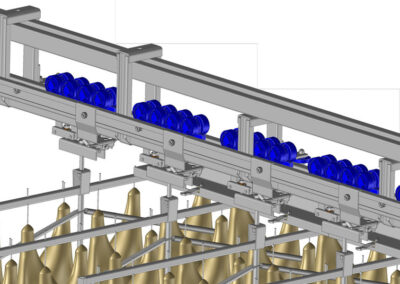

trolleys

Thanks to our long-standing experience in this field, we have developed a wide range of trolley. Each trolley has different characteristics depending on the load it must carry and on the working temperature.

- WHEELS

available with different diameters, made of NYLON for working temperature till 80 °C or made of a special compound for working temperature from 80 to 120 °C

Ball bearing of stainless steel on request.

- TROLLEY BODIES

are made of stainless steel, coated with thoughened technopolymer or they are obtained by stainless steel precision casting. - END CAPS

Irreversible interlocking with provision for insertion of a TAG for tracking systems.

wheels

Ø 60

Ø 70

Ø 90

Ø 102

Ø 110

Ø 70

Ø 90

Ø 102

Ø 110