VACUUM TUMBLER

The new series of MENOZZI VACUUM TUMBLER has been improved to achieve even higher quality and efficiency standards.

APPLICATIONS AND PERFORMANCE

The particular “spoon shape” of the internal fins and their inclination, together with the vacuum (continuous or pulsed) system activates an osmotic massage that ensures a homogeneous absorption of the ingredients into the meat also with short massaging time. This reduces the stress of the product and its consequent increment of temperature. The versatility of the massaging system allows to obtain the best results of processing with different kinds of meat, whether they are whole or in pieces, to be treated with injected solutions or dry salt.

PROGRAMMING PARAMETERS

The software allows to memorize 32 recipes, each one consisting of 4 processing phases and

customizable with the following parameters:

• Rotation speed

• Rotation direction: clockwise/counter-clockwise

• Duration of the complete working cycle

• Time of pause

• Vacuum time

• Pulsating vacuum/ continuous vacuum

Further to this the software manages also:

• Alarm system and self-diagnosis of malfunctions

• Maintenance guide

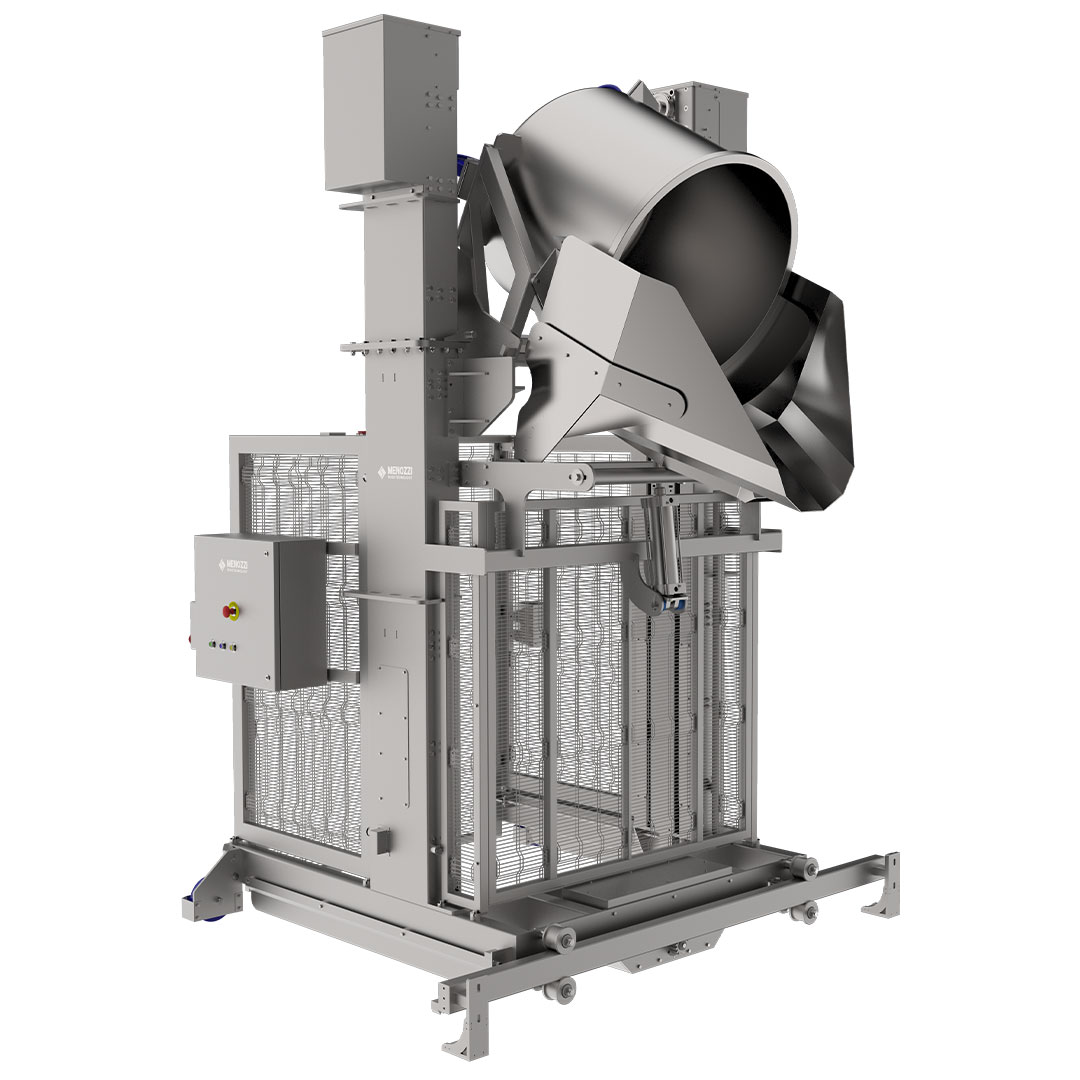

CLEANING AND SANITIZING

- The maximum tilt angle reached by the tumbler permits the liquids to flow away very well, that allows an effective washing avoiding stagnation of residuals.

- The internal surface of the drum is easily and totally accessible from the exterior for inspection, cleaning and microbiological sanitation.

- The quick release protection panels allow the operator to access the machine within a few seconds for clearing and routine maintenance.

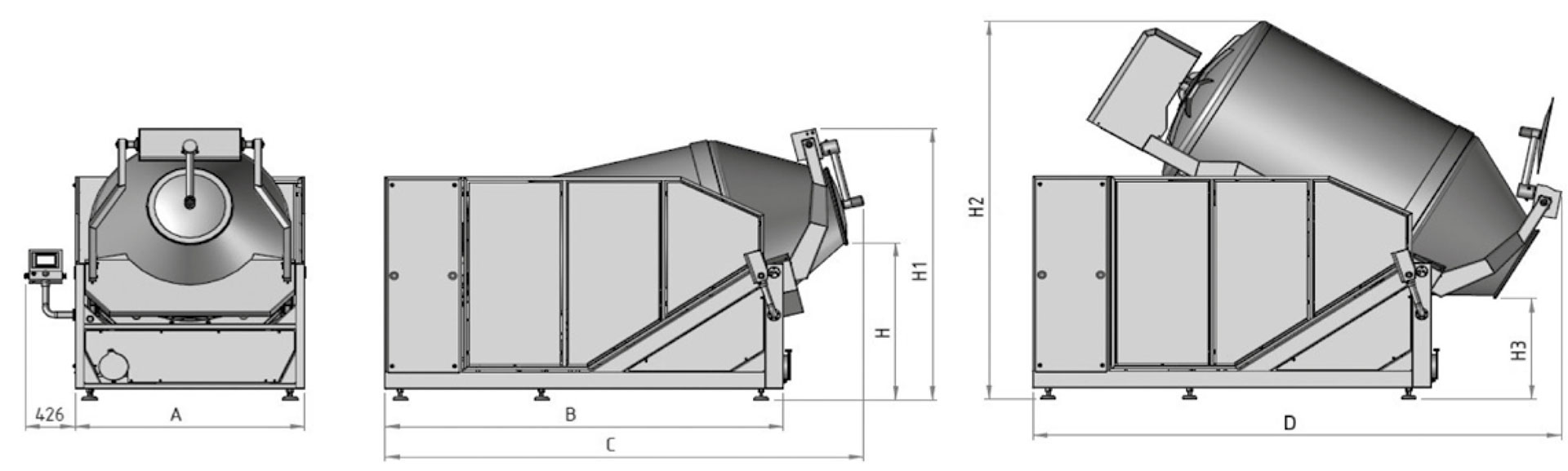

vacuum tumbler range

tumbler 700

|

Load capacity max 700 kg |

| Volume of the drum 1200 lt |

| Separate utilities cabinet |

| Vacuum pump 63 m³/h |

| Manual lid opening |

tumbler 1400

|

Load capacity max 1400 kg |

| Volume of the drum 2400 lt |

| Electric lid, frontal opening /closing |

| Vacuum pump 100 mm³/h |

| Utilities cabinet on board |

tumbler 2400

|

Load capacity max 2400 kg |

| Volume of the drum 4000 lt |

| Electric lid, frontal opening /closing |

| Vacuum pump 100 mm³/h |

| Utilities cabinet on board |

tumbler 3500

|

Load capacity max 3500 kg |

| Volume of the drum 5800 lt |

| Electric lid, frontal opening /closing |

| Vacuum pump 150 m³/h |

| Utilities cabinet on board |

STANDARD ACCESSORIES FOR ALL MACHINES

- IP69K touch screen control panel equipped with two-hand control

- Electric lid electric lid frontal opening/closing with finger protection system

- Vacuum system

- Vacuum tank

- Hydraulic tilting system

- Quick release protection panels

optional accessories

Refrigerated-heated jacketing with automatic thermal control

Automatic discharging program, 8 discharging steps

load cells with integrated weight display

Pneumatic lid, side opening

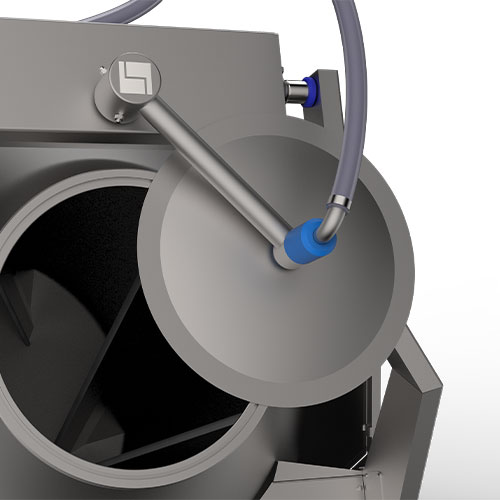

automatic brine loading system

Thermal probe for product temperature control

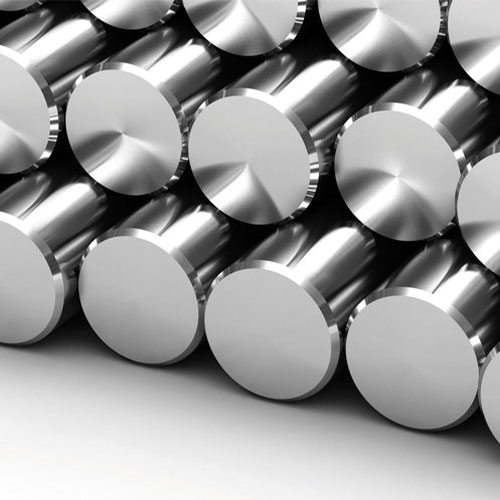

optional finishes

Mirror- polishing of the internal surface of the drum

AISI 316 steel

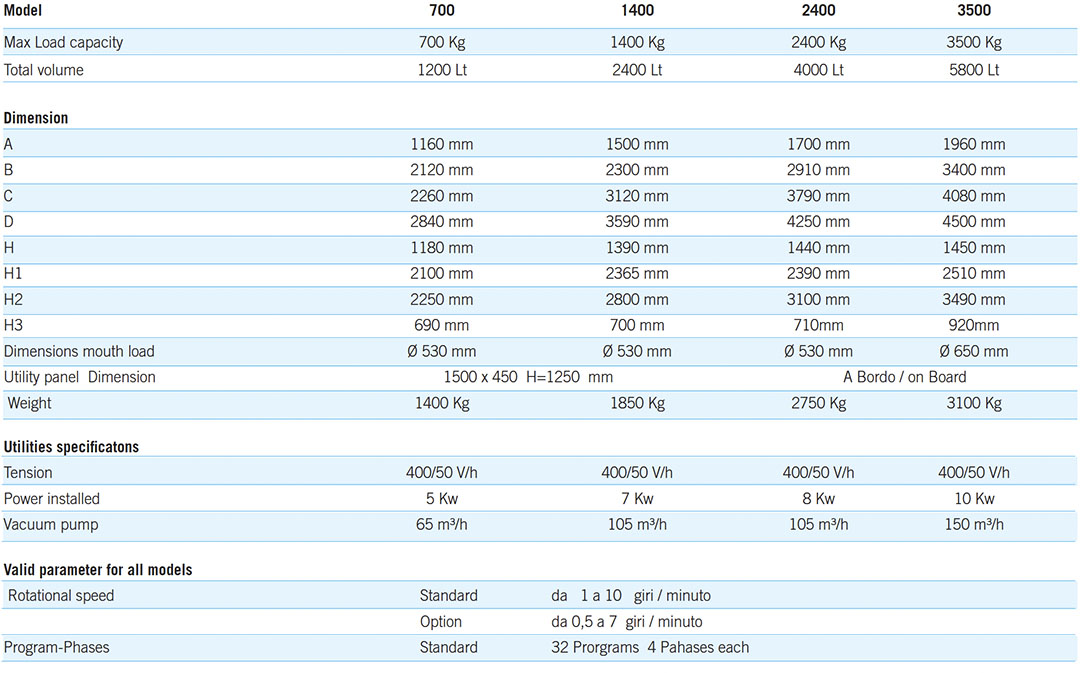

types of loader

tumbler filling and emptying

The tumbler can be loaded:

• By tilting-lifter for 200/300l trolleys or for bigger bins

• By conveyor belts

The unloading is obtained by the gradual and controlled tilting of the drum , avoiding sudden fall of product and loss of liquid.

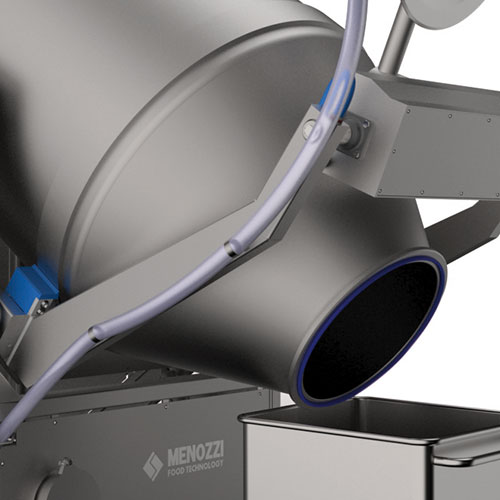

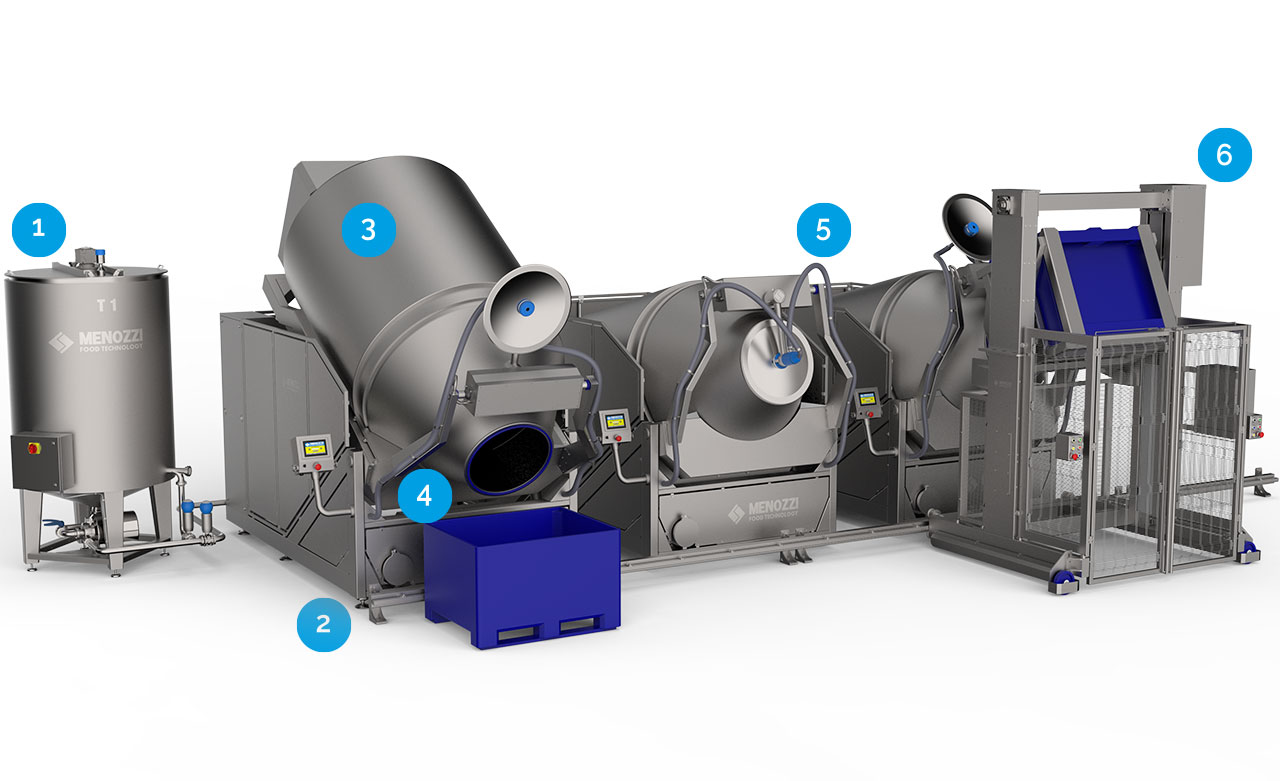

complete massaging system

with brine storage tank and automatica brine transfer to the tumblers

| Brine storage tank | |

| Load cells | |

| Jacketing for cooling and temperature control | |

| Automatic unloading system | |

| Automatic brine loading system | |

| Electric loader wit motorized axial movement on rail |